2024-03-12 04:40:3688 have been browsing

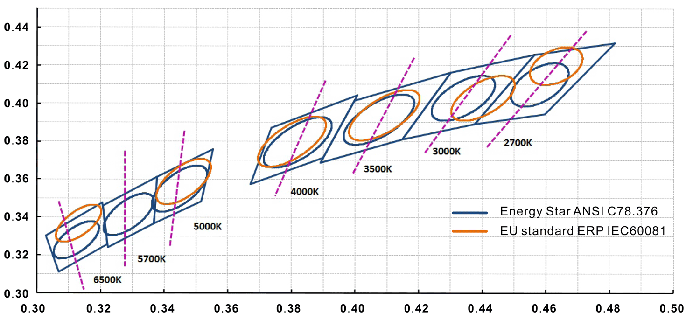

The following is a 3rd-order comparison diagram of the IEC standard and the ANSI standard.

1. It can be seen from the figure that the standard color temperature coordinate center points of IEC and ANSI standards are different, and the difference of 6500K, 3000K, and 2700K is the most obvious.

So you must first confirm with the supplier what standard to use as a reference when you place the order. (DERUN LIGHTING USE EUROPEAN STANDARD)

2. The correspondence between color temperature and SDCM causes some problems:

When referring to the standard color temperature versus color, due to the interval constraint of the color temperature of each standard SDCM of the standard color temperature, the color temperature range of the actual demand product is narrowed, resulting in unreasonable product requirements.

Example.

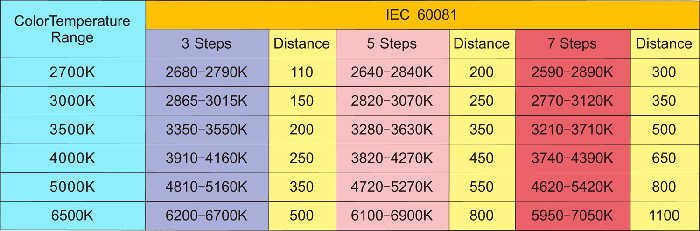

If the customer needs 3000-3300K, the European standard and the SDCM is less than five steps. We can find out that the relevant color temperature range required by the customer is included in both 3000K and 3500K according to the following IEC standard table.

Referring to the five steps of 3000K, it is (2820-3070K), then the range of the required requirements is only 70K (3000K-3070K). If it refers to the five steps range of 3500K, it is (3280-3630K), only about 20K (3280-3300K) color temperature, the product is difficult to meet the demand.

Therefore, the correlation color temperature range we give must be within a reasonable range, and the size of this range needs to be determined by the specific field of accuracy that the supplier can control.

The following is a 3rd-order comparison diagram of the IEC standard and the ANSI standard.

The-Impact-of-International-Standard-on-SDCM

1. It can be seen from the figure that the standard color temperature coordinate center points of IEC and ANSI standards are different, and the difference of 6500K, 3000K, and 2700K is the most obvious.

So you must first confirm with the supplier what standard to use as a reference when you place the order. (DERUN LIGHTING USE EUROPEAN STANDARD)

2. The correspondence between color temperature and SDCM causes some problems:

When referring to the standard color temperature versus color, due to the interval constraint of the color temperature of each standard SDCM of the standard color temperature, the color temperature range of the actual demand product is narrowed, resulting in unreasonable product requirements.

Example.

If the customer needs 3000-3300K, the European standard and the SDCM is less than five steps. We can find out that the relevant color temperature range required by the customer is included in both 3000K and 3500K according to the following IEC standard table.

Referring to the five steps of 3000K, it is (2820-3070K), then the range of the required requirements is only 70K (3000K-3070K). If it refers to the five steps range of 3500K, it is (3280-3630K), only about 20K (3280-3300K) color temperature, the product is difficult to meet the demand.

Color-tolerance-iec-60081

Therefore, the correlation color temperature range we give must be within a reasonable range, and the size of this range needs to be determined by the specific field of accuracy that the supplier can control.

3. SDCM shift problem caused by machine difference

If there is a significant deviation between the standard parts of the two suppliers, even if the SDCM is the same standard, the difference in the value of the test is still huge.

It’s not because the coordinate value of the center point of the SDCM is not the same, but the standard of the machine. The center point offset caused by the standard deviation of the device, so be sure to confirm the color again after replacing the supplier.